Thermoplastic olefin (TPO) are polymer/filler blends usually consisting of some fraction of a thermoplastic and an elastomer. Thermoplastics may include polypropylene (PP), polyethylene (PE), Copolymers of PE etc. Some times it may consist some fillers. The TPOs need to be designed based on application needs. TPOs are most cost effective compared to TPEs or Elastomers and most cases it can give the desired properties keeping the costs low.

Thermoplastic Elastomers (TPEs) are melt processable soft polymers which behave like elastomers. TPEs are recyclable and typically consists of a combination of a soft and hard black morphology.Some are blends or alloys of crystalline and amorphous polymers, some are block co-polymers comprised of blocks of crystalline and amorphous domains along the same polymer chain. TPEs provide excellent design flexibility in addition to easy processabiity in convention thermoplastic machinery like injection molding. TPEs are designed based on cost vs performance needs. A wide range of formulations are possible and customization is essential to arrive at right cost and performance balance.

EVA is the material of choice for soft, light and high performing footwear because of its low density, flexibility and adhesion performance. In recent years the trend is changing towards softer, flexible and higher performing soles. Traditionally 18% VA containing EVA are popular and 28% VA materials are making their entry. To achieve super softness combined with good foam properties it requires much softer base material.

Inventive Polymers is offering a modified EVA Compound with32% to 40% VA content EVA that can be used partially along with 18% or 28% VA containing EVA to achieve foam hardness below 50 on asker C scale.

Advantages

1. Can help in making foam softer

2. High crosslinking density

3. Soft touch

4. Aesthetic appearance

Polyamides have limitations interms of flexibility, processability and moisture absorption. Range of specialty polyamides are developed to address the industry needs.

Some of them are

1. Flexible Polyamides(Nylon 6) for tubing applications

2. High gloss Polyamides for paint replacement applications

3. High viscous & flexible polyamides for blow molding applications.

Plastic painting is a tedious process and needs dealing with large amount of volatile solvents. High gloss Polyamides enable customers to eliminate the painting in several applications including automotive outdoor applications. Please get on touch with us to discuss your specific need.

Nexapol developed a range of EVA compounds for injection molding and extrusion applications. Applications include Rail pads, Insulation pads, Extrusion coating compounds, Cable jacketing compounds for low voltage and Bellows.

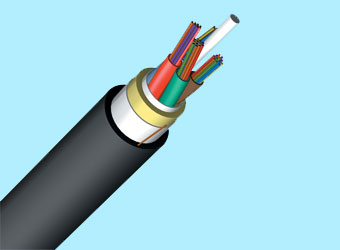

Nexapol developed a range for speciality coating material for optical fiber industry.

1. EAA Coating material

Extrusion coating material for mega bond. FRP EAA coating increases bonding between FRP & Polyethylene.

2. Water based water block coating

Nexapol developed water block coating material based on water carrrier. After coating, the water dries

and makes a permanent coating. Can be coated on glass fiber or FRP rod.

3. Solid hot melt water block coating

Nexapol developed a hot melt based water blocking material which can be coated with simple

melt process. It can be coated on FRP rod.